Bar Stock

The StarFeed is an automated loader/unloader for the StarCut Tube laser cutting machine and is available in sizes S and L. This combination allows fully automated dry or wet cutting of tubes from 1-20 mm diameter. The StarFeed L stores up to 48 tubes and even allows the processing of oval tubes. Its sensor-controlled gripping unit avoids damage. The end result is a big increase in productivity.

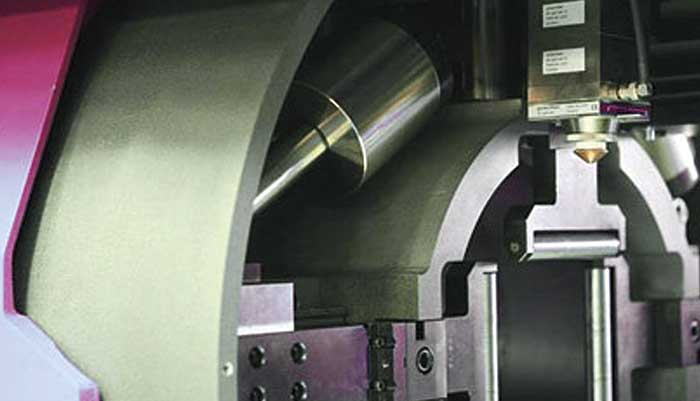

Lasertube systems, our 2D or 3D laser cutting system for tubes, bars, profiles and tubes from 12 mm up to 610mm (.5" to 24-") in diameter and 18 m (60") in length, are called Lasertube systems.